Open source continues to drive rapid innovation in the 3D printing industry. This makes sense if you stop and think about it—a 3D printer exists to make other things. Combining that philosophy with free software and open source hardware helps other people participate in improving the objects that it makes, and in making the printers faster, smarter, and cleaner.

Here are a few of my favorite open source 3D printing innovations from 2016:

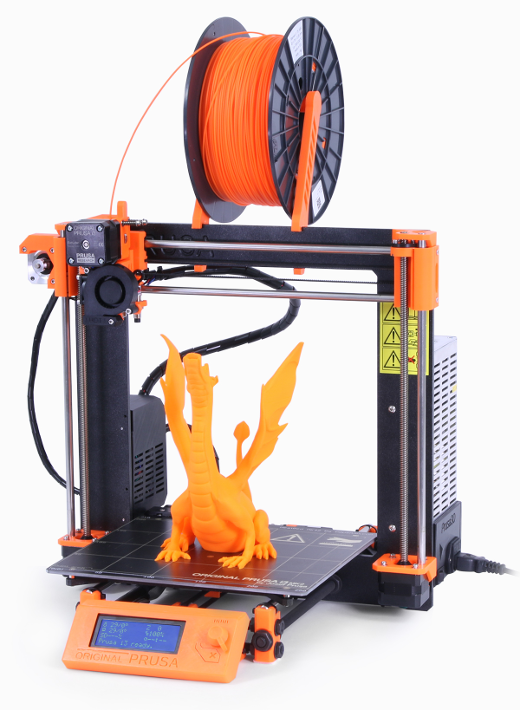

Prusa i3 MK2

Courtesy of prusa3d.com

Josef Průša is one of the core developers of the RepRap project, and the line of printers that bears his name continues to get better and better, without sacrificing any of the open source goodness that makes it possible. In 2016, the Prusa I3 MK2 3D printer was released, and it is the first printer to correct its geometry in all axes automatically. This means that you no longer have to be as concerned about how precisely the printer is assembled or calibrated—the firmware included in the printer will do everything it can to ensure that the prints come out perfect. The printer uses nine special calibration points on the printer bed, combined with a probe that detects those points, then determines the deviation (if any) on the X and Y axes. This allows the printer to recalculate and adjust for any skew. It uses the same input to determine the Z height at all of the calibration points and adjust as needed. This technique is called mesh bed leveling and it eliminates most (if not all) imperfections in the bed.

There's a lot more math and engineering to explain how all of this works, but the end result is better prints every time, all powered with open source firmware and hardware. For a deeper dive into how it works, learn more on the Prusa Printers site, or watch this video:

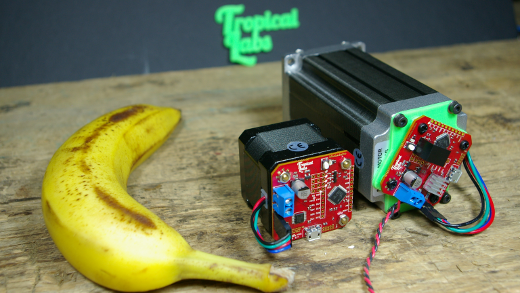

Mechaduino

3D printers are usually powered by NEMA stepper motors. The motors turn belts, which cause the printer to move in three dimensions. The motors are cheap and simple, but not terribly accurate. To get accuracy, you usually want to use industrial servo motors, but they aren't cheap or simple. Enter Tropical Labs and their Mechaduino.

Mechaduino is an open source industrial servo control platform that provides a combination of the low cost of mass-produced stepper motors with high-resolution accuracy. Their vision is to be the “Arduino for mechatronics". Although this innovative board will have a big impact on a number of different electronics projects, the fact that this can be a drop-in addition to most 3D printers makes it very exciting to me. Lots of people agreed, as this easily got funded via Kickstarter, reaching 855% of their goal.

3D printing with clay

Tom Lauerman. CC BY-SA 4.0

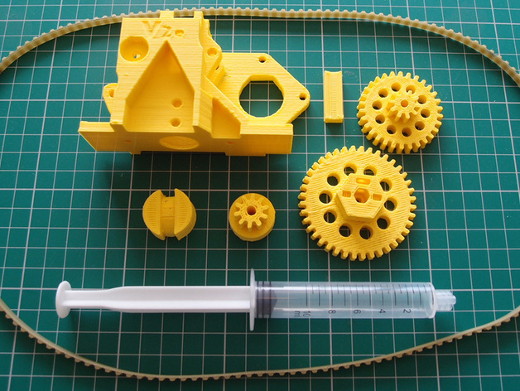

Most 3D printers use plastic filament or resin. A few use more exotic materials, such as sugar or chocolate, but Tom Lauerman wanted to use clay. Lauerman, an assistant professor at Penn State, designed his own 3D printer in collaboration with the University's Learning Factory program and the Center for Innovative Material Processing through Direct Digital Deposition (CIMP-3D). Unlike some academic printer projects, the Bricoleur Clay Extruder wasn't built from scratch, patented, documented in an academic paper that few would ever read, and then shelved in a dusty basement on campus. Lauerman built upon existing open source 3D clay print head designs, and as a result, he remained committed to releasing all of his designs under an open source license so that others could print and improve upon his design.

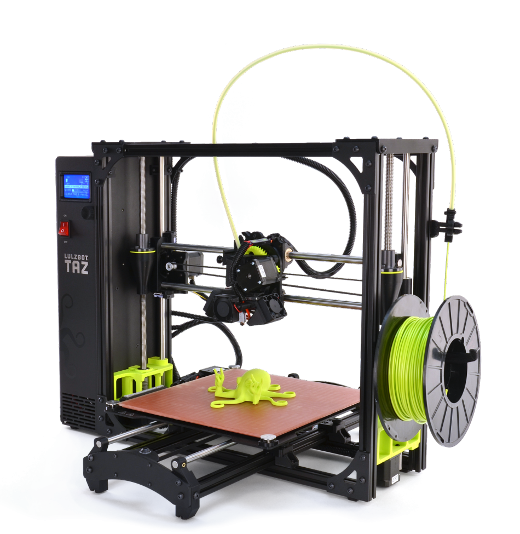

Lulzbot TAZ 6

I am a huge fan of the Lulzbot printers, and the TAZ 6, released in 2016, is no different. There is a reason that it is “Earth's highest rated desktop 3D printer," and that reason is freedom. Everything that goes into the TAZ 6 is free as in freedom—the firmware that drives it, the parts that compose it, the software that controls it—there is no secret sauce in this printer. The TAZ 6 is yet another proof point that open source does not mean sloppy or beta.

The printer itself contains a large number of 3D-printed pieces, printed on a fleet of other TAZ printers. Freedom and open source are part of the Lulzbot DNA, and the parent company (Aleph Objects) actively works with their community to come up with hacks, improvements, and modifications to make the printer more robust, accurate, and intelligent. The result of this transparency, remixing, and collaboration is a simple yet powerful 3D printing experience that appeals to an audience from students to maker gurus.

(Full disclosure: We use Lulzbot 3d printers in the Red Hat 3D printing lab at the Red Hat headquarters in Raleigh, North Carolina.)

Open source bioprinting

Early in 2016, Ourobotics, an Irish 3D bioprinting startup, introduced the Renegade, an open source bioprinter that can be assembled for under US$ 900. This printer is based on Richard Horne's Universal Paste Extruder. For much of the 3D printing community, bioprinting is seen as a holy grail of the technology. If we can print replacement organs, then we can improve and save lives around the world. We're not quite there yet, but Ourobotics saw the value of innovating in the open source way to help us get to that goal faster and more affordably.

Sadly, in August, the CEO of Ourobotics, Jemma Redmond passed away unexpectedly. One of the small comforts of open source work is the knowledge that those projects can live on, even after we are gone from this world.

7 Comments