Smart composite parts, from carbon fiber to nanocomposites, are transforming our everyday lives. So much so, even the White House is interested.

In the first decade of the twentieth century, science advanced material structures and content to a point where, when coupled with technology, we can now produce new, advanced materials. Think of a modern prosthetic leg: Advances in smart composite parts have allowed us to combine new materials like carbon fiber with technology to create robotic limbs that a person can move and feel.

We live in a convergence era of infinite computation, sensors, and materials that can be combined to create brand new possibilities. One of the elements pushing these boundaries is customization, where the product becomes the process design. For example, we could develop the same product, but because of our different processes, the resulting product is likely to be different.

Community

The speed of making a material transition from concept to production has increased and the cost has decreased exponentially. Decades ago, it would take you years and thousands of dollars to develop a product, but now it may take you hours and less than one hundred dollars. This has happened because digital manufacturing is now mostly open source and open design, allowing people to utilize a community to create a better product.

Developing materials using an ecosystem of co-creation, based on open design with open source software, provides the capability to rapidly develop and deliver a new product to market faster, most efficiently, and cheaper.

New software will continue bringing renewed dynamics to advanced materials science and speed up the ability to co-create, thus boosting the value of next generation composite parts by allowing people to build on top of existing models.

Digital manufacturing

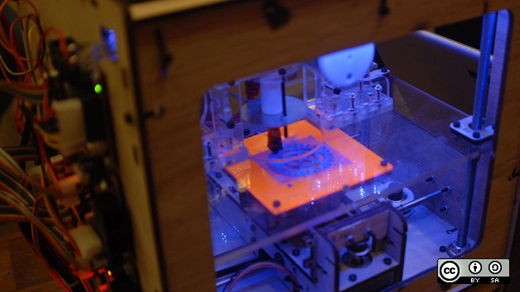

Coding material with data enables us to reach a new digital manufacturing era. For instance, take F-35 fighter jets. Engineers use 3D printing to digitally manufacture 900 parts for the plane, on demand, providing supply chain savings and increasing the speed of distribution.

As digital manufacturing evolves and provides an ecosystem for co-innovation and open design, the next chapter of advanced materials will be shaped by integrating open source 3D printers, CAD software, computer numerical control (CNC), and laser cutters to create smart manufacturing. Imagine creating a CAD model, exporting the data, and printing the product all from a single appliance.

The future of advanced material innovation starts with combining open source software and open design into a single platform. This unlocks creativity and harnesses the power of copyleft collaboration. We are starting to see the beginning of this revolution. DARPA in collaboration with Local Motors, recently turned to the general public to design a future combat support vehicle. Whereas the typical development cycle of a vehicle takes five years, within fourteen weeks, the combined knowledge of the community produced the XC2V FLYPMode: a potential replacement for the Humvee.

To get to the next step will require an extraordinary level of collaboration to help solve complex challenges. The advent of digital manufacturing will require an unprecedented level of collaboration to bring this disrupted innovation process to reality. Revolution is in the making as we integrate material science, hi-tech, sensors, and tools in a chaotic environment. Innovation flourishes when the playing field is open and ignites ample creativity.

However, digital manufacturing has a long way to go to reach the complete integration and adoption. As an analogy, we are only in the “minicomputer and hobbyist era” of this revolution. To reach the integrated PCs level, we must learn how to assemble the content into an integrated printing solution.

One day, customization in digital manufacturing will be as easy as simply printing a document from your PC.

Originally posted on the DLT blog, Technically Speaking. Reposted using Creative Commons.

3 Comments