Open source has touched a lot of scientific disciplines, but one area where it is missing is soil science. Until recently, you could only find it in educational materials. A team from the Université de Lorraine, INRAE in France, and Western University in Canada bring open source to the soil science community.

Soil science experiments saw significant impact by the technological advances developed over the past decades. However, support for these experiments evolved very slowly, and soil science literally languished in the dirt. Researchers still take soil samples in the "traditional" way from specific fields. For this purpose, agricultural researchers determine which areas might contain the most suitable soil for an experiment in advance. This method leads to many approximations and uncontrolled parameters, which significantly complicates the analysis of the results. Thus, some studies require identical replicates. 3D printing offers an excellent opportunity to meet this need.

(Joshua Pearce, cc-by-sa-nc)

Modeling a porous structure for soil science must consider a combination of specifications (nature of the material, porosity, and location of specific substances or living organisms). In addition, using an engineering design approach improves the modeling process, and these become customizable and reproducible models—some of the bedrock properties of open source science. The model's main characteristics are identified and studied according to the complexity of the specific soil phenomena. With that modeling, you can achieve a design approach for defining a manufacturing process.

One main challenge to support this design approach is developing software that allows soil scientists to create soil models according to their needs in terms of the soil structure. This software should be dedicated to scientific research and promote data sharing and exchange across an international community.

Reproducing soil samples digitally helps academics and researchers conduct reproducible and participatory research networks that help better understand the specific soil parameters. One of the most critical challenges for soil modeling is the manufacturing of a soil structure. Until now, the most widespread method to replicate porous soil structures is using X-ray tomography to scan an actual sample. This process is expensive and time-consuming and does not readily provide an approach to customization. A new open source approach makes it possible for any soil scientist to design a porous soil structure. It is based on mathematical models rather than the dirty samples themselves—allowing researchers to design and parameterize their samples according to their desired experiments.

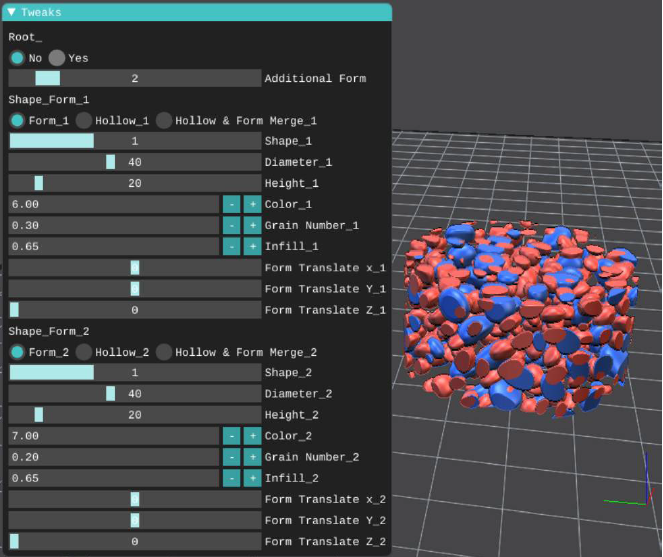

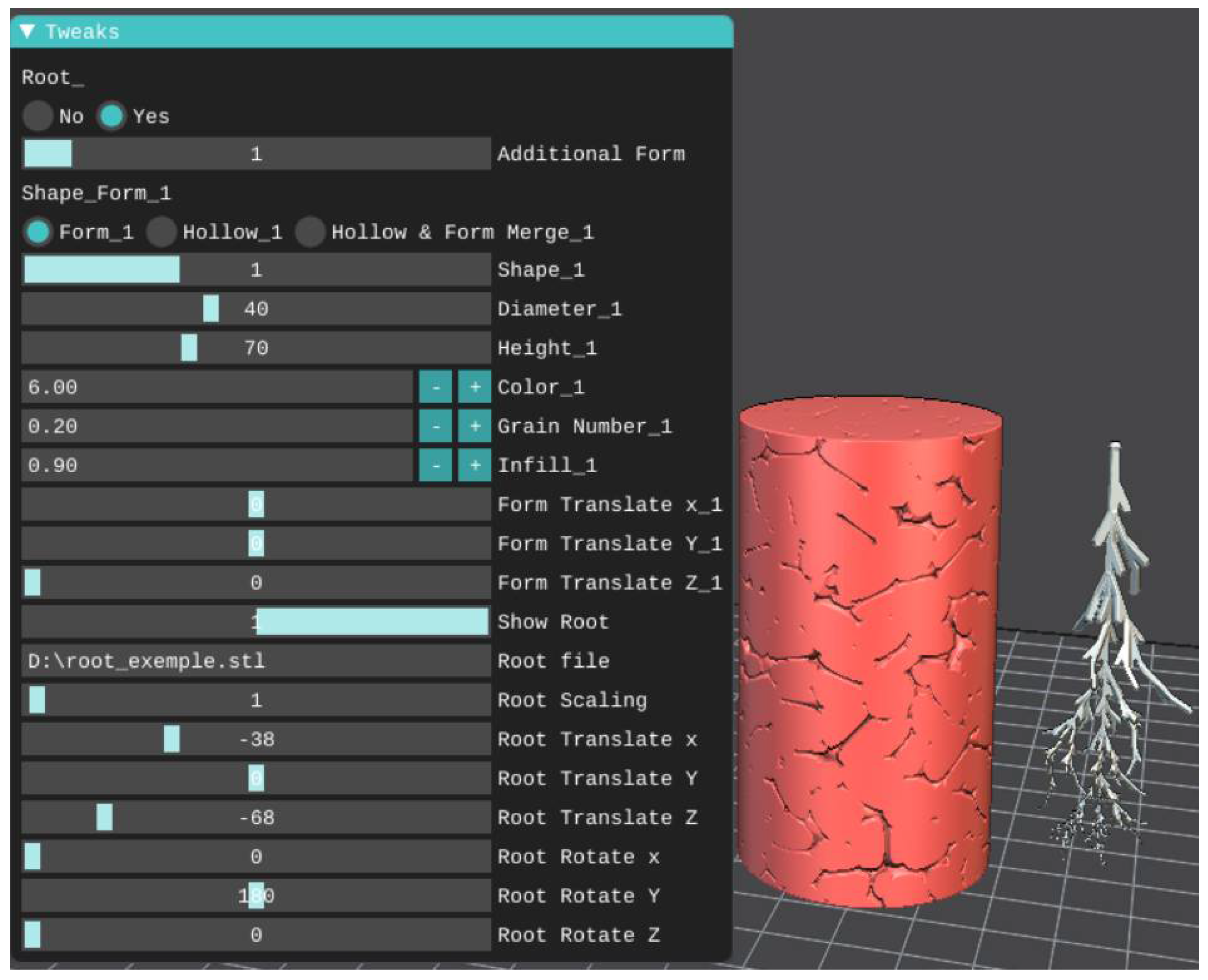

(Joshua Pearce, CC BY-SA 4.0)

Developing an open source toolchain using a Lua script, in the IceSL slicer with a GUI enables researchers to create and configure their digital soil models, called monoliths. Done without using meshing algorithms or STereoLithography (STL) files because those reduce the model's resolution.

Monolith examples are fabricated in polylactic acid using open source fused filament fabrication technology with a layer thickness of 0.20, 0.12, and 0.08 mm. The images generated from the digital model slicing are analyzed using open source ImageJ software. ImageJ provides information about internal geometrical shape (porosity, tortuosity, grain size distribution, and hydraulic conductivities). The results show that the developed script enables designing reproducible numerical models that imitate soil structures with defined pore and grain sizes in a range between coarse sand (from 1 mm diameter) to fine gravel (up to 12 mm diameter).

(Joshua Pearce, CC BY-SA 4.0)

Samples generated using the developed script would be expected to increase reproducibility and be more accessible because of the open source and low-cost methods involved.

You can read the complete open access study here: Open-Source Script for Design and 3D Printing of Porous Structures for Soil Science by Romain Bedell, Alaa Hassan, Anne-Julie Tinet, Javier Arrieta-Escobar, Delphine Derrien, Marie-France Dignac, Vincent Boly, Stéphanie Ouvrard, and Joshua M. Pearce 2021, published in Technologies 9, no. 3: 67.

Comments are closed.